Product description:

The double-walled plate heat exchanger plate effectively prevents fluid leakage and mixing to meet the specific needs of your product.

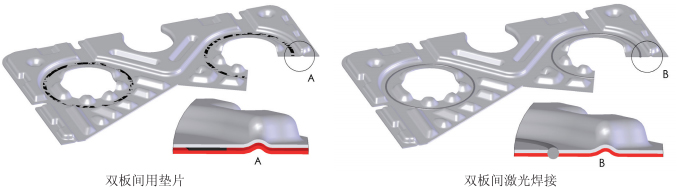

The heat exchanger plate is replaced by two single-plate one-piece stamping double plates, and the sealing between the two plates is realized by laser welding or flat washers of the four-hole portion of the plate. In the event of a leak, the fluid will flow out of the flow path between the two plates to the outside, which can be easily detected and taken to avoid fluid mixing during heat exchange, resulting in contamination or harmful reactions. Combined with the double seal of the gasket, the possibility of mixing two materials is avoided, and it is suitable for applications with high hygienic requirements or industrial production safety and reliability. Since the two sheets are welded to form one sheet, the heat transfer coefficient of the sheet is inevitably lowered, but the safety of the insulating material is high.

Features:

Make sure that the two materials do not mix.

Leakage can be detected visually.

Double plate laser welding.

No pressure regulating equipment is required for operation.

Application range:

Capacity floor: 0.1m3/h to 300m3/h

Operating pressure: ≤2.5MpaG

Operating temperature: ≤150°C

Plate material: stainless steel 304, 316L, Ti, Ti-Pd, 904L, SMO254, Hastelloy, nickel Ni

Gasket materials: NBR, EPDM, HNBR, FKM (VITON-A, VITON-B, VITON-G).

PRODUCTS

PRODUCTS SOLUTIONS

SOLUTIONS